E. Katz, M. Pita, Biofuel cells controlled by logically processed biochemical signals: Towards physiologically regulated bioelectronic devices. (Concept paper) Chem. Eur. J. 2009, 15, 12554-12564.

|

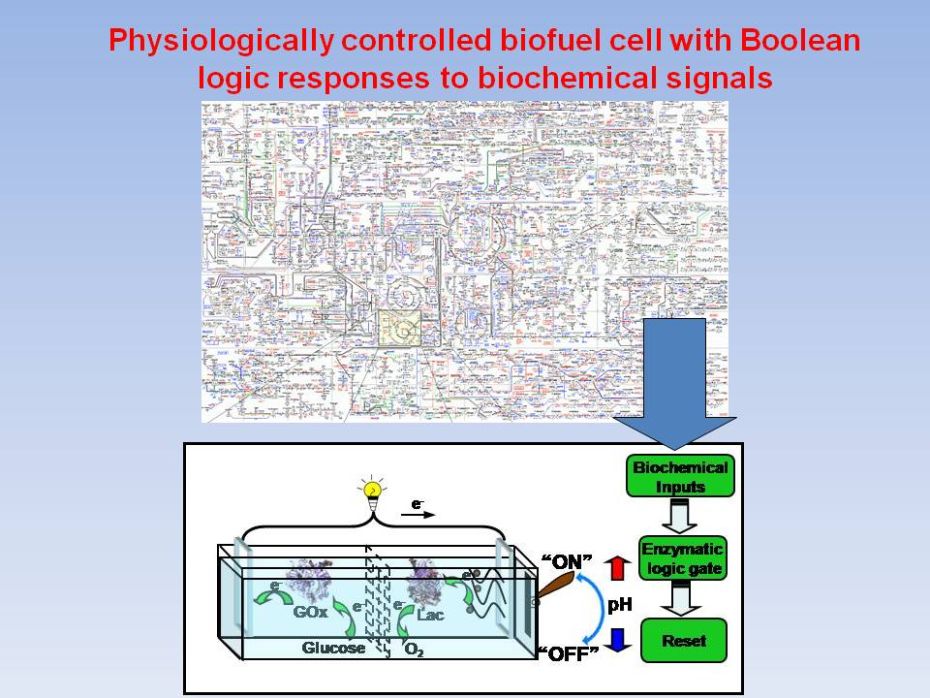

Biofuel cells with switchable power

release controlled by biochemical signals logically processed by

biomoleculer computing systems have been designed. The switchable

properties of the biofuel cells were based on the

polymer-brush-modified electrodes with the activity dependent on the

solution pH value. The pH changes generated in situ by biocatalytic

reactions allowed the reversible activation – inactivation of the

bioelectrocatalytic interfaces, thus affecting the activity of the

entire biofuel cells. Boolean logic operations performed by either

enzymes- or immuno-based systems were functionally integrated with the

switchable biocatalytic process allowing logic control over them.

Scaling up the complexity of the biocomputing systems to complex

multi-component logic networks with built-in “program” resulted in the

control of the bioelectronic systems by multi-signal patterns of

biochemical inputs. Future implantable biofuel cells producing

electrical power on-demand depending on physiological conditions are

feasible as the result of the present research. E. Katz, M. Pita, Biofuel cells controlled by logically processed biochemical signals: Towards physiologically regulated bioelectronic devices. (Concept paper) Chem. Eur. J. 2009, 15, 12554-12564. |

|

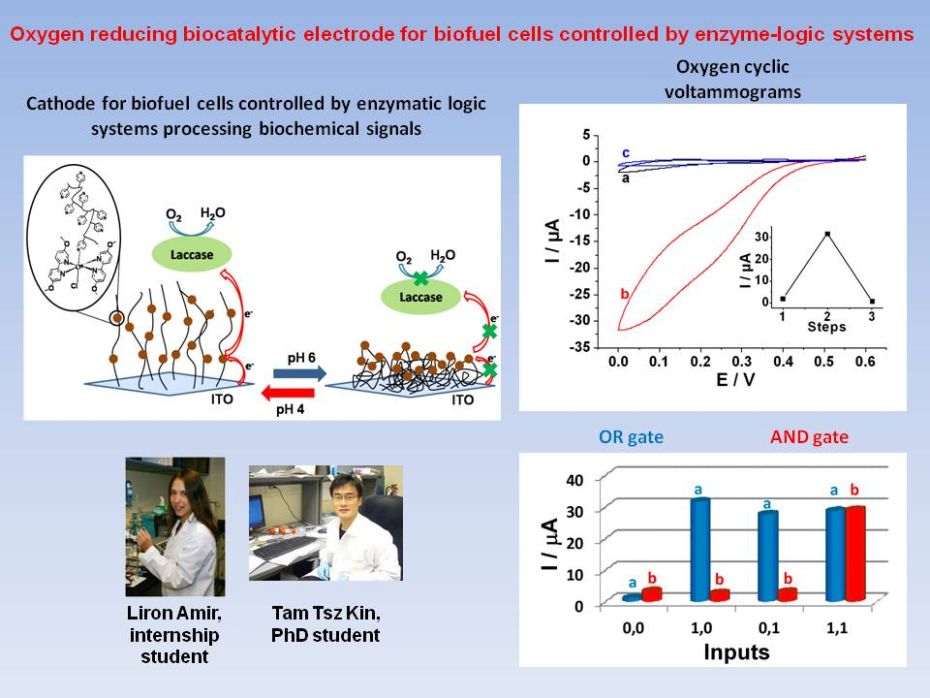

Biofuel Cell Controlled

by Enzyme Logic Systems

An enzyme-based biofuel cell with a

pH-switchable oxygen electrode, controlled by enzyme logic operations

processing in situ biochemical input signals, has been developed. Two

Boolean logic gates (AND / OR) were assembled from enzyme systems to

process biochemical signals and to convert them logically into

pH-changes of the solution. The cathode used in the biofuel cell was

modified with a polymer-brush functionalized with Os-complex redox

species operating as relay units to mediate electron transport between

the conductive support and soluble laccase biocatalyzing oxygen

reduction. The electrochemical activity of the modified electrode was

switchable by alteration of the solution pH value. The electrode was

electrochemically mute at pH > 5.5 and it was activated for the

bioelectrocatalytic oxygen reduction at pH < 4.5. The sharp

transition between the inactive and active states was used to control

the electrode activity by external enzymatic systems operating as logic

switches in the system. The enzyme logic systems were decreasing the pH

value upon appropriate combinations of the biochemical signals

corresponding to the AND / OR Boolean logic. Then the pH-switchable

electrode was activated for the oxygen reduction and the entire biofuel

cell was switched ON. The biofuel cell was also switched OFF by another

biochemical signal which resets the pH value to the original neutral

value. The present biofuel cell is the first prototype of a future

implantable biofuel cell controlled by complex biochemical reactions to

deliver power on-demand responding in a logic way to the physiological

needs.

L. Amir, T.K. Tam, M. Pita, M.M. Meijler, L. Alfonta, E. Katz, J. Am. Chem. Soc. 2009, 131, 826-832. |

|

|

|

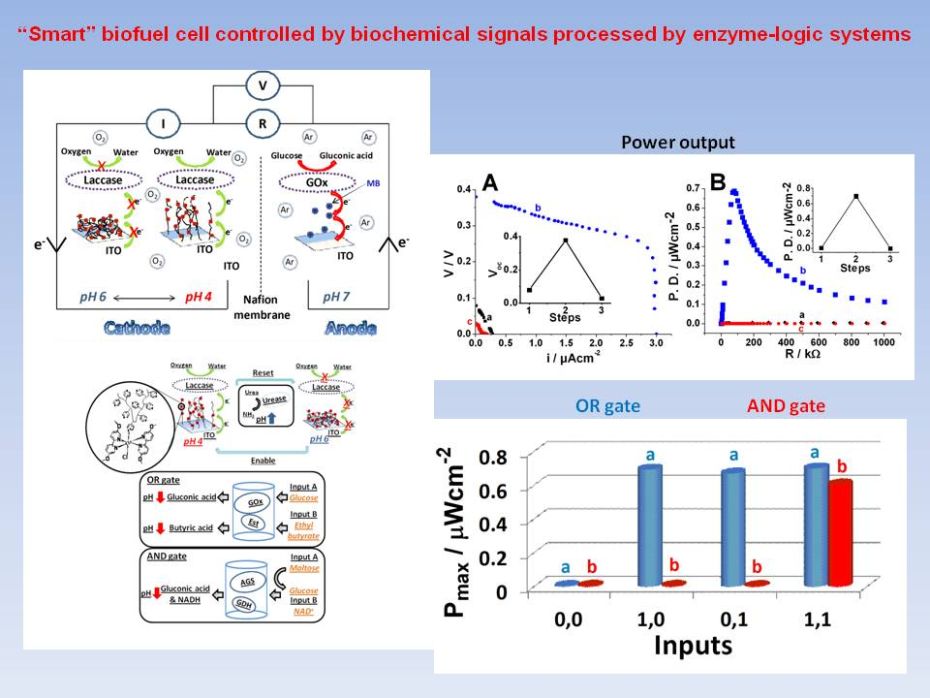

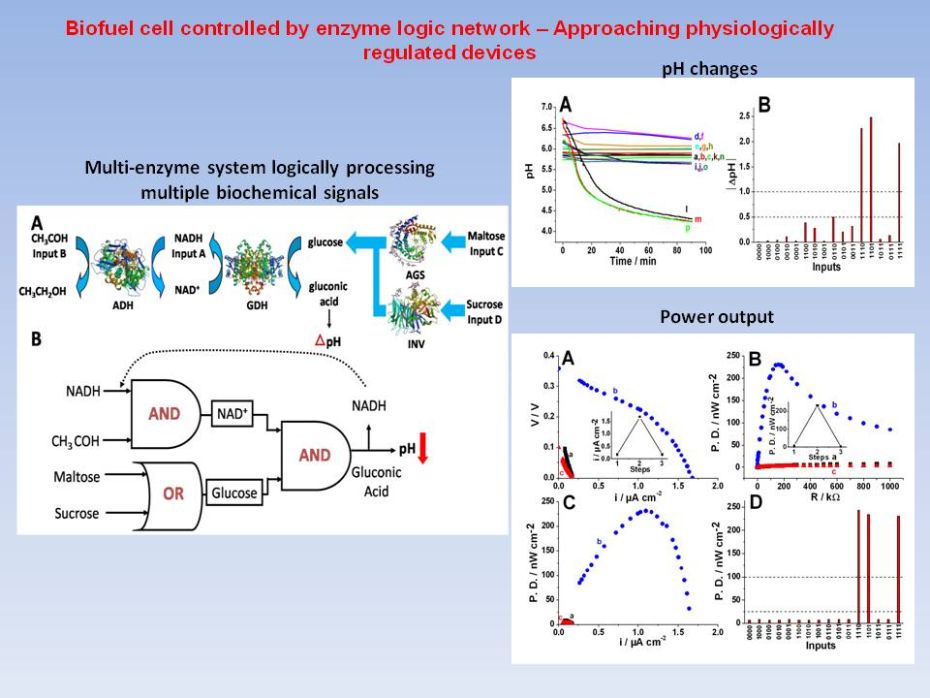

Biofuel Cell Controlled

by Enzyme Logic Network – Approaching Physiologically Regulated Devices

A

“smart” biofuel cell switchable ON

and OFF upon application of several chemical signals processed by an

enzyme logic network was designed. The biocomputing system performing

logic operations on the input signals was composed of four enzymes:

alcohol dehydrogenase (ADH), amyloglucosidase (AGS), invertase (INV)

and glucose dehydrogenase (GDH). These enzymes were activated by

different combinations of chemical input signals: NADH, acetaldehyde,

maltose and sucrose. The sequence of biochemical reactions catalyzed by

the enzymes models a logic network composed of concatenated AND / OR gates. Upon application of

specific “successful” patterns of the chemical input signals, the

cascade of biochemical reactions resulted in the formation of gluconic

acid, thus producing acidic pH in the solution. This resulted in the

activation of a pH-sensitive redox-polymer-modified cathode in the

biofuel cell, thus, switching ON the entire cell and dramatically

increasing its power output. Application of another chemical signal

(urea in the presence of urease) resulted in the return to the initial

neutral pH value, when the O2-reducing cathode and the

entire cell are in the mute state. The reversible

activation-inactivation of the biofuel cell was controlled by the

enzymatic reactions logically processing a number of chemical input

signals applied in different combinations. The studied biofuel cell

exemplifies a new kind of bioelectronic devices where the bioelectronic

function is controlled by a biocomputing system. Such devices will

provide a new dimension in bioelectronics and biocomputing benefiting

from the integration of both concepts.

T.K. Tam, M. Pita, M. Ornatska, E. Katz, Bioelectrochemistry 2009, 76, 4-9. |